- E-mail:

Jenny.Jaa@czsns.cn - Tel/WeChat:

0086-15295106006

The severe duty motors with their robust cast iron housing are the first choice for all major applications in normal industrial environments, as well as in harsh environments. They are very reliabl,e even under extreme conditions, versatile, extremely compact, and easy to handle. Very high efficiencies ensure economical and sustainable operation.

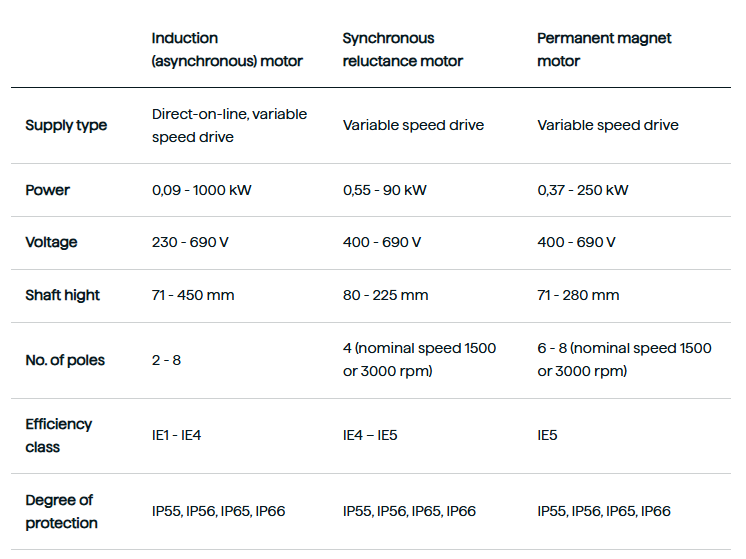

In addition to induction (asynchronous) motors for direct-on-line and converter operation, two different synchronous motor technologies are available. These need to be used always with a frequency converter (VSD).

The proven induction motors from the Innomotics SD Severe Duty Motors are optimized for line operation, and are available with efficiency classes up to IE4. The IE4 class became mandatory since July 2023 for safe area motors with nominal power 75 – 200 kW and 2 – 6 poles, placed on the market in the European Economic Area.

However the Innomotics SD portfolio is greatly exceeding these regulations by offering IE4 designs from 2.2 to 1000 kW, up to 8 poles. Additional catalog variants are available, such as the highly compact Increased Power Line motors, featuring one step smaller shaft height. Find more information about the Innomotics portfolio in the IE4 class below.

The grid-optimized motors can also be operated with converters.

The variable-speed-drive motors are based on the platform of the Innomotics SD Severe Duty Motors. The design corresponds to the line motors – the mechanical parts are identical. However, instead of the squirrel cage induction rotor, they utilize one of the two available synchronous technologies. Together with an appropriate frequency converter they provide an outstanding performance and reach an extremely high energy efficiency (IE4 or IE5), also at partial loads. In addition, a large number of the variations available for the line motors (types of construction, motor protection, terminal box position, and options) are also available for the VSD motors.

Synchronous reluctance motor

For particularly energy-efficient operation, with keeping the standard power-shaft height assignment, the best choice is a VSD system with an Innomotics reluctance motor. The reluctance technology, without any rotor winding, ensures particularly high dynamic performance and high efficiencies even in the partial load range, as well as high process quality.

Permanent magnet motors

This advanced technology with permanent magnets in the rotor enables not only an outstanding IE5 energy efficiency, but also a high power density. The permanent magnet motor can be even three frame sizes smaller than an induction motor of the same power rating. Furthermore these motors provide a constant torque from the lowest speed and cover high overloads and overspeeds.

Find out more: Innomotics PM Permanent Magnet Motors