- E-mail:

Jenny.Jaa@czsns.cn - Tel/WeChat:

0086-15295106006

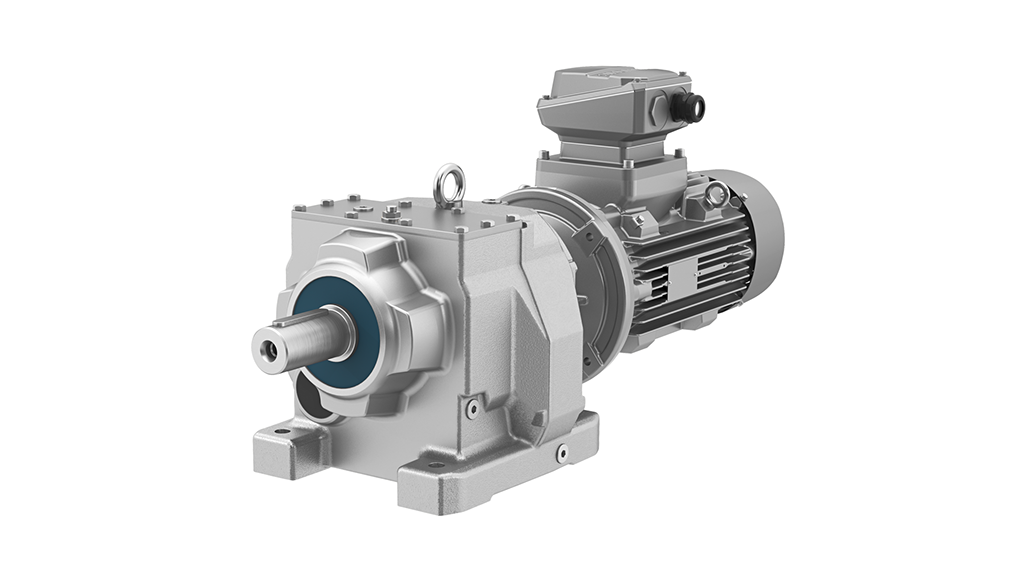

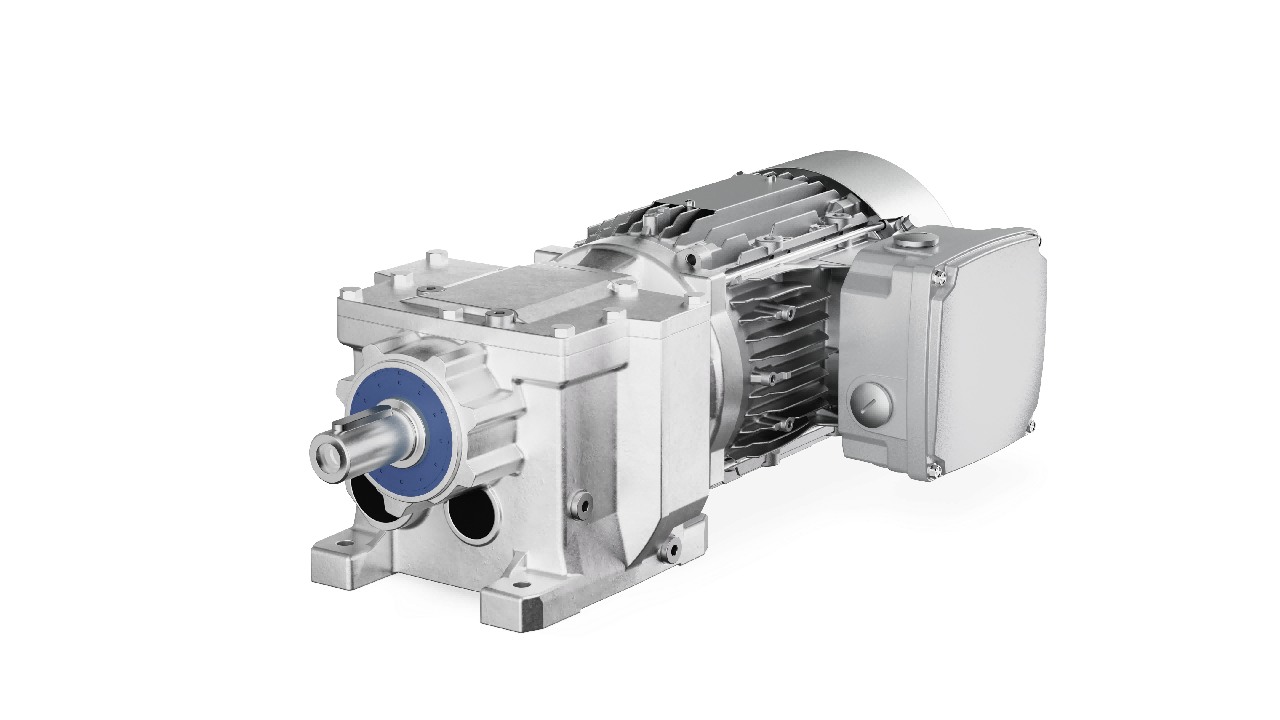

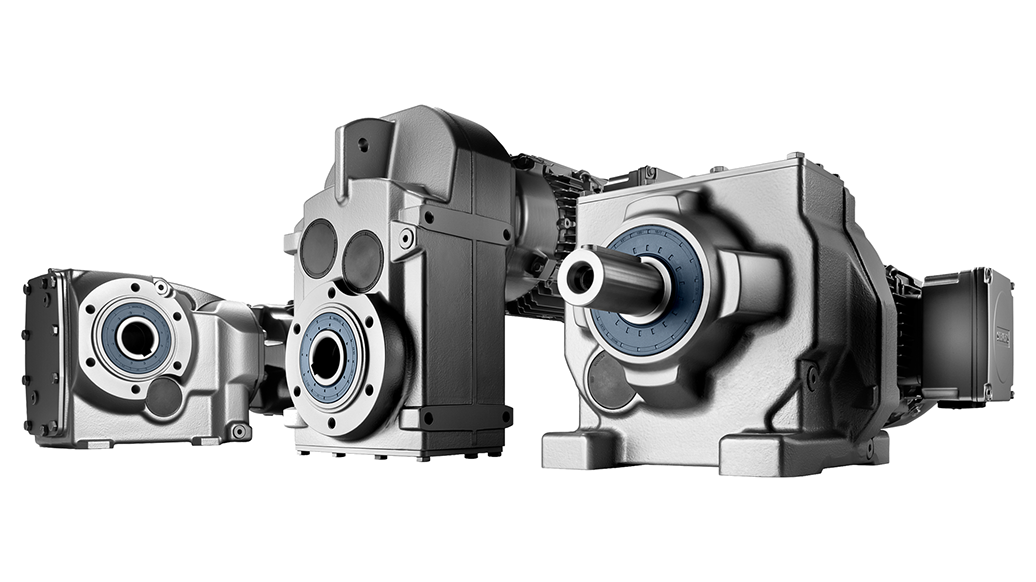

Our extensive range of geared motors ensures that you will find the optimal product for your needs. With the new Innomotics SG Geared Motors you will benefit especially from its ability to deliver the highest level of flexibility due to our wide range of gear units, total adaptability and compact design.

The Innomotics SG Geared Motor portfolio is extensive and you can always find the optimum geared motor that precisely meets your requirements. We have expanded our portfolio even further – you can now combine Innomotics gearboxes with a wider range of Innomotics motors in the TIA Selection Tool* and obtain a complete, all-in-one solution as a single package. The whole system is easily configured using the tool – all available motor combinations are calculated and approved in terms of mechanics, geometrics and thermal conditions. Ordering and delivery of this one-package solution is a simple procedure.

We are introducing the new Converter World Motor that is fully compatible to SINAMICS* frequency converters. It is a geared motor with IE3 efficiency class, optimized for converter operation and available in a power range from 0.37 kW to 55 kW. It is a "world motor" – which means it has one motor winding as standard for all of the major global certificates of approval. The motor is optimized for all line voltages from 380 V up to 480 V, therefore always ensuring maximum performance. Needless to say, it is integrated into tools such as the TIA Portal*, TIA Selection Tool* and Drive Technology Configurator*.

Innomotics Explosion Protected Geared Motors can be operated in hazardous zones. Safety is of paramount importance in these types of environments, and these efficient motors can safely operate under extreme conditions for long periods of time. They are based on rugged, premium quality motors that have been tried and tested worldwide. The result is a seamless range of motors addressing customer requirements with a maximum degree of safety and the highest operational efficiency. We have expanded the explosion protected portfolio to include an integrated version where an adapter is not required. For applications in Zone 2 (gas) and Zone 22 (dust), an adapter is not required between the motor and gearbox – thus reducing the complexity and making dimensioning and selection easier

They are easy to service thanks to the synchronous-reluctance solution therefore representing an excellent choice when selecting a drive system with high energy efficiency.

The synchronous-reluctance solution can be applied in many different domains, and it has many important technical benefits when compared to standard asynchronous motors. These motors maintain a stable speed even without encoder, and it is also possible to achieve a high permanent overload in the higher speed range.

The system is typically used to control roller, chain and belt conveyors in airport baggage and cargo handling facilities. It is also a great fit for warehouses and distribution logistics including packaging and mail handling areas. It is commonly used in hoisting equipment, scissor lift tables and monorail conveyors as well as for skids used in the automotive industry.

Innomotics is offering the compact and versatile geared motor solutions that can be optimally integrated into the drive train. Always both precise and powerful. More flexibility, more power, a more standard approach – these are the expectations of the sector, especially in conveyor technology.

Innomotics gear motor delivers performance from 0.09 kW up to 55 kW. It can achieve a gear unit torque up to 19.500 Nm with helical, parallel shaft, helical bevel and worm geared gear units, additional types and sizes. Due to accordance to the current measures, Innomotics geared motor is compatible to many other suppliers of geared motors. The new series of Innomotics geared motors is 1:1 compatible to the general standard in the market, and can therefore be simply integrated into existing or new machines and systems.

Helical geared motors reach high gear ratios thanks to shank pinion. They provide very economic performance as well as they are high energy efficient (efficiencies 98% per stage). Available as well in high power range. They are offered with one, two or three stages in foot and flange-mounting version with solid shaft. Innomotics Helical Geared Motors among others find the application in conveyor belts, when transporting packaged goods and in vertical conveyors.

Bevel geared motors can also reach high gear ratios and they are highly energy efficient (efficiencies 98% per stage). They are able to achieve high gear ratios and have high power density. They can be even used in narrow constructions so they can be used in places with delimited spatial conditions. They are offered in stages two and three in foot or flange-mounting version with solid or hollow shafts. Innomotics bevel geared motors are used for baggage and material handling conveyors, rope lifts in warehouse logistics and for carriage drives.

Innomotics Parallel Shaft Geared Motors

Parallel shaft geared motors are also suitable to use in narrow construction spaces. They boast with high energy efficiency (efficiencies of 98% per stage). Innomotics parallel shaft geared motors reach high gear ratios thanks to the plug-in pinion. Is it possible to place hollow shaft on both sides. They have two or three stages and are mounted with foot or flange-mounting, housing flange or shaft mounting with torque arm. They can be provided with solid shaft, hollow shaft, splined hollow shaft or hollow shaft with shrink disc. They are typically used for agitator drives, carriage drives, shelf access equipment and vertical conveyors.

Worm geared motors are very silent and represent an economic solution especially for low power ranges. They achieve high gear ratios and can be also used in narrow spaces thanks to their compact design. Available with one or two stages and are being offered in foot or flange-mounting versions. Innomotics worm geared motors boast with ShaftMount - keyless tapered hollow shaft locking system. They are being offered with solid or hollow shafts. These types of motors are usually used for small conveyor belts and other conveyor system or for rope lifts by example.

Helical worm geared motors are offered in 2 stage version. The mounting offering includes solid and hollow shafts. They are energy efficient and usually chosen when demand for drives with angular geared motors. Due to worm gear stage, high ratios can be implemented. Innomotics helical worm geared motors represent the cost-effective solution for angular geared motors in the lower torque range. They achieve extremely low noise and are used by example in waste water system and as drives in theaters