- E-mail:

Jenny.Jaa@czsns.cn - Tel/WeChat:

0086-15295106006

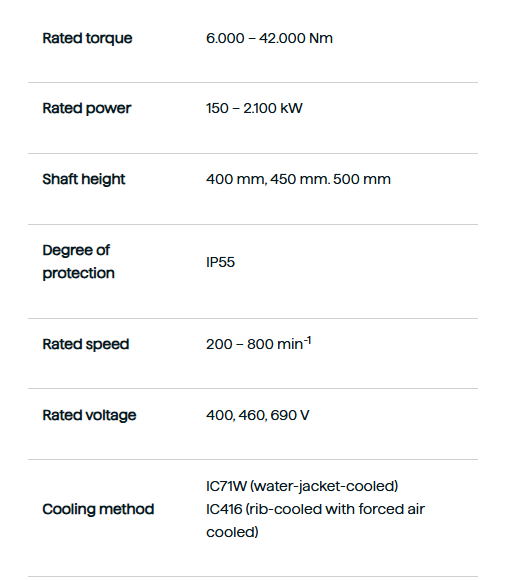

The high torque motors are permanent-magnet synchronous motors that can provide high torques at low speeds directly at the driven machine. High efficiencies and good power factors can also be achieved at low speeds as a result of the permanent magnet rotors. The high torque motor in combination with a converter represents a drive solution with a long service lifetime but with low lifecycle costs and high efficiency for applications with low operating speeds. Benefits applications With slow-running drives, the efficiency of the Innomotics High Torque Motors is approximately 2 to 3% higher than for similar drive concepts, if gear or gear steps can be saved. For a 1000 kW motor, this results in a saving of 33 kW, which is an annual saving of approximately, 15000€ for an operating time of 8 hours per day. High pole design in combination with permanent magnet technology ensures that the space requirement and mass of the motors are lower than for similar asynchronous machines. The slow-running motors of the Innomotics High Torque Motors obviate the need for a gearbox in many cases (reduction in engineering, assembly and maintenance outlay, lower investment and lower operating costs). Efficient, optimally matched drive system, SINAMICS* converter and Innomotics High Torque Motors for operation with or without encoders Thanks to their long service life (nominal bearing lifetime > 60000 hours), Innomotics High Torque Motors are maintenance-free and have a high availability especially for applications in which a gearbox can be omitted Environmentally friendly system (where applicable, no disposal of gearbox oil is necessary; energy-saving drive system). Customization is possible. Applications where the following are important - high efficiency, low space requirements with low lifecycle costs for the drive solution. The main application of the Innomotics DP Definite Purpose Motors – High Torque Motors areas are as follows: Paper industry as roller and press drive Marine industry as propeller drive (main and auxiliary drives) Mining industry for mill drives Steel industry e.g. for shears Plastics industry as drive for extruder worms, foil-drawing machines Crane industry for the widest range of applications Sugar industry for sugar centrifuges Branch Chemical Industry, Oil Gas Branche Water / Waste waterTechnical data overview

Applicationsmatch